In the demanding realms of aerospace and defense, ensuring that products can withstand the rigors of high-altitude environments is paramount. MIL-STD 810 is a Department of Defense Test Standard for environmental engineering considerations and laboratory tests. Method 500 in MIL-STD-810 defines procedures for low-pressure (altitude) testing. The latest revision of this method is 500.6 from MIL-STD-810H.

Altitude Testing Services at Delserro Engineering Solutions

At Delserro Engineering Solutions, our altitude testing services are designed to meet the rigorous demands of the aerospace and defense industries. By employing the comprehensive procedures outlined in MIL-STD-810H Method 500.6, we ensure that every product undergoes thorough low pressure testing under simulated high-altitude conditions. The altitude test chambers at Delserro Engineering Solutions (DES) can meet the requirements of MIL-STD-810H (and previous revisions) accurately ensuring that products are not just compliant but are primed for operational excellence.

MIL-STD-810 altitude testing services are tailored to products that:

- Operate or are stored at significant elevations.

- Experience pressurized or unpressurized conditions in aircraft.

- Could undergo rapid or explosive decompression.

- Are externally mounted on aircraft and exposed to extreme conditions.

Method 500 is not intended for items that are installed or operated in space vehicles, aircraft, or missiles that fly at altitudes above 21,300 m (70,000 ft).

The following are typical failures that could occur from products used in a high altitude (low pressure) environment:

- Leakage of gases or fluids from gasket-sealed enclosures

- Deformation, rupture, or explosion of sealed containers

- Change in physical and chemical properties of low-density materials

- Overheating of materiel due to reduced heat transfer

- Evaporation of lubricants

- Erratic starting and operation of engines

- Failure of hermetic seals

- Erratic operation or malfunction of materiel resulting from arcing or corona

MIL-STD-810 Method 500.6 Insights for Low Pressure Testing

MIL-STD-810 Method 500.6 has four procedures:

- Procedure I – Storage/Air Transport. Procedure I is for testing material that is transported or stored at high ground elevations or transported by air in its shipping/storage configuration.

- Procedure II – Operation/Air Carriage. Procedure II is used to test the performance of products operated at high altitudes. It may be preceded by Procedure I.

- Procedure III – Rapid Decompression. Procedure III is for determining if a rapid decrease in cabin pressure will cause a failure or malfunction that would endanger nearby personnel the ground vehicle or the aircraft in which it is being transported.

- Procedure IV – Explosive Decompression. Procedure IV is similar to Procedure III except that it involves an instantaneous decrease in pressure.

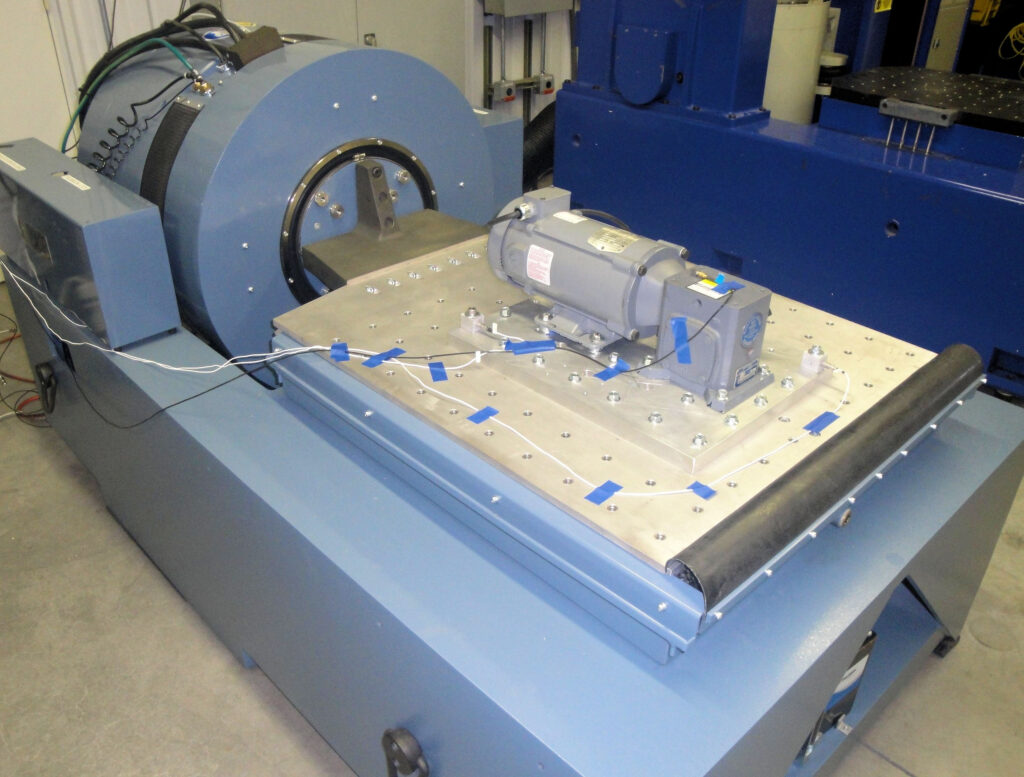

How is MIL-STD-810 Low Pressure Testing performed? First, it is necessary to determine the test parameters such as test altitude (pressure) and temperature, rate of change of pressure (and temperature if appropriate), duration of exposure, and test item configuration based upon the Life Cycle Environmental Profile. Once the parameters are defined, low pressure testing is performed by placing the specimen in a specialized chamber that simulates altitude by controlling pressure and temperature. Upon completion of the altitude test, DES will promptly deliver a detailed test report that includes the customer’s name and address, the test dates, a summary of the test procedure, equipment & measuring system calibration information, plots of altitude and temperature, test observations & results, color pictures of the altitude test setup and color pictures of any failures.

Why Choose DES for MIL-STD-810 Low Pressure (Altitude) Testing

- A2LA Accreditation: Our laboratory’s accreditation is a testament to our commitment to quality and excellence in environmental testing. DES is A2LA accredited to MIL-STD-810 Low Pressure (Altitude) Testing.

- Trusted by Industry Leaders: Our state-of-the-art testing facilities, experienced engineering team, and track record of success has made us the number one choice of top defense contractors.

- Advanced Testing Capabilities: With equipment capable of simulating altitudes from below sea level to as high as 1,000,000 feet and temperatures ranging from -75°C to +150°C, we can accommodate a wide variety of testing requirements.

Contact us today to discuss how our altitude testing services can contribute to the success and reliability of your next project.