ISTA 1 tests are Non-Simulation Integrity Performance Tests meant to evaluate the strength and robustness of the product and package combination. Each of the ISTA 1 test procedures (1A, 1B, 1C, 1D, 1E, 1G, and 1H) include a combination of tests to assess the ability of packaging to withstand different transportation hazards. These tests help manufacturers and distributors identify weaknesses in their packaging and product designs, and ultimately make improvements to ensure products arrive at their destinations in good condition. All ISTA 1 tests share the common goal of minimizing potential shipping issues and product damage during transportation.

What are the benefits of ISTA Series 1 Package Tests? They can:

- Evaluate the durability of individually packaged products

- Compare the performance of various package and product design alternatives

- Test that your products will arrive unharmed at their destination

- Provide a cost-effective screening test to evaluate potential shipping issues or product damage

- Shorten package development time and gain confidence before launching products

The ISTA 1 tests are divided into the following procedures:

- ISTA 1A, Integrity Testing for Packaged-Products weighing 150 lb. (68 kg) or Less

- ISTA 1B, Integrity Testing Packaged-Products weighing Over 150 lb. (68 kg)

- ISTA 1C, Extended Integrity Testing for Individual Packaged-Products weighing 150 lb. (68 kg) or Less

- ISTA 1D, Extended Integrity Testing for Individual Packaged-Products weighing Over 150 lb. (68 kg)

- ISTA 1E, Integrity Testing for Unitized Loads

- ISTA 1G, Packaged-Products weighing 150 lb. (68 kg) or Less utilizing Random Vibration

- ISTA 1H, Integrity Testing for Packaged-Products weighing Over 150 lb. (68 kg) utilizing Random Vibration

ISTA 1A to ISTA 1E: Packaging Up to 150 Pounds and above (1B, 1D, 1E)

ISTA 1A Package Testing

ISTA 1A is a package test procedure for individually packaged products weighing up to 150 pounds. The table below provides the test sequence required for ISTA 1A. ISTA 1A is the same as ISTA 1G except for the vibration. ISTA 1A uses fixed displacement vibration while ISTA 1G specifies random vibration.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Vibration | Fixed Displacement | Required |

| 3 | Shock (alternative methods allowed-select one test type) | Package Drop Test or Inclined Impact or Horizontal Impact | Required |

ISTA 1B Package Testing

ISTA 1B is a protocol for individually packaged products weighing more than 150 pounds. ISTA 1B is the same as ISTA 1H except that ISTA 1B specifies fixed displacement vibration whereas 1H uses random vibration. The table below provides the test sequence required for ISTA 1B.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Vibration | Fixed Displacement | Required |

| 3 | Shock (alternative methods allowed-select one test type) | Package Drop Test (6 in) or Inclined Impact (69 in/sec) or Horizontal Impact (69 in/sec) | Required |

| 4 | Shock | Rotational Edge Drop (8 in) | Required when not testing face 1 |

ISTA 1C Package Testing

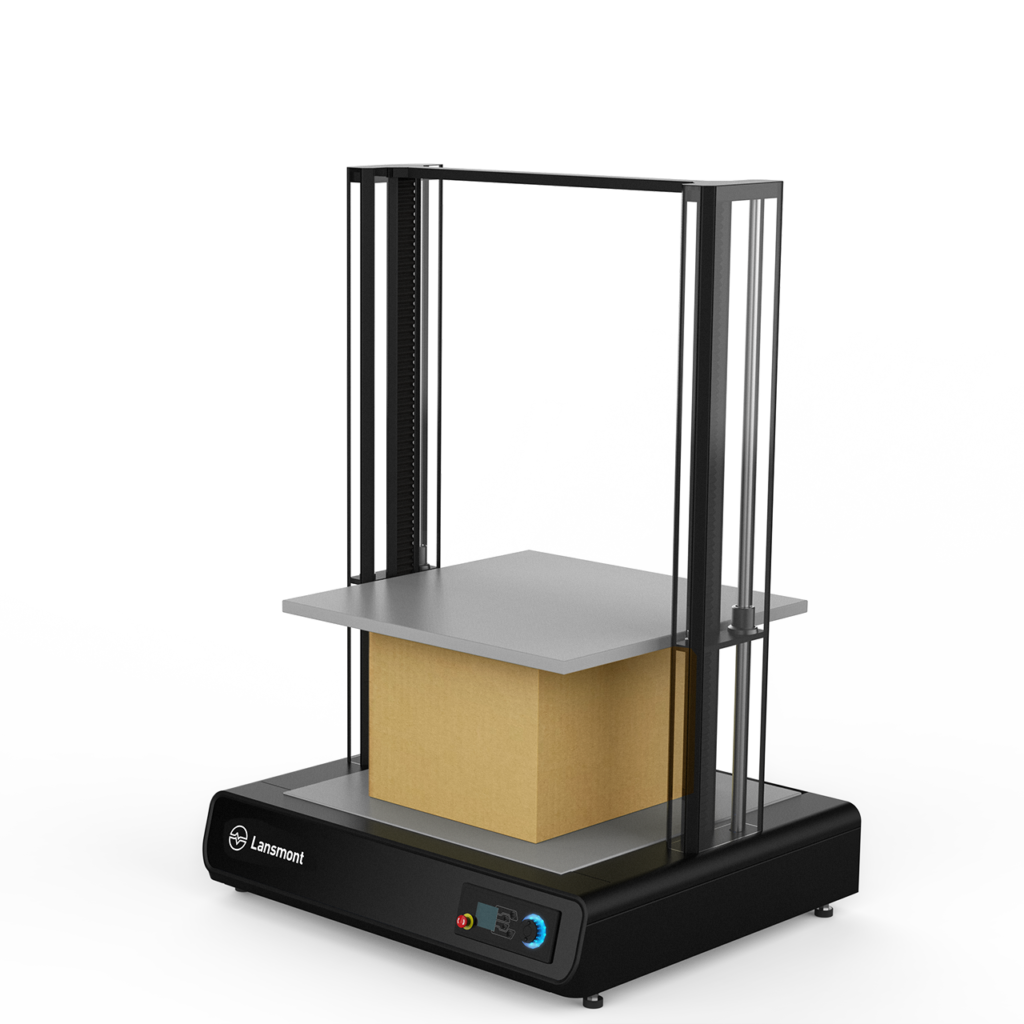

ISTA 1C is an extended package test procedure designed for individually packaged products weighing 150 pounds or less. ISTA 1C adds compression testing vs. 1A or 1G and gives alternative choices for vibration. The test sequence is listed below.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Compression Testing (alternative methods allowed-select one test type) | Compression Tester, apply and release Compression Tester, apply and hold Weight and Load Spreader | Required |

| 3 | Vibration (alternative methods allowed-select one test type) | Fixed Displacement or Random Vibration | Required |

| 4 | Shock (alternative methods allowed-select one test type) | Package Drop Test or Inclined Impact or Horizontal Impact | Required |

ISTA 1D Package Testing

ISTA 1D is an extended test protocol for individually packaged products weighing more than 150 pounds. ISTA 1D is the same as 1B or 1H with the addition of compression testing and alternative choices for vibration. The test sequence is shown below.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Compression Testing (alternative methods allowed-select one test type) | Compression Tester, apply and release Compression Tester, apply and hold Weight and Load Spreader | Required |

| 3 | Vibration (alternative methods allowed-select one test type) | Fixed Displacement or Random Vibration | Required |

| 4 | Shock (alternative methods allowed-select one test type) | Package Drop Test (6 in) or Inclined Impact (69 in/sec) or Horizontal Impact (69 in/sec) | Required |

| 5 | Shock | Rotational Edge Drop (8 in) | Required when not testing face 1 |

ISTA 1E Package Testing

ISTA 1E is for testing unitized (palletized) loads made up of either single or multiple products or packages of the same products. The test sequence is shown below.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Vibration (alternative methods allowed-select one test type) | Fixed Displacement or Random Vibration | Required |

| 3 | Shock (alternative methods allowed-select one test type) | Inclined Impact (69 in/sec) or Horizontal Impact (69 in/sec) | Required |

| 4 | Shock | Rotational Edge Drop (8 in) | Required |

Vibration and Shock Testing for Packages Up to 150 lb (ISTA 1G) & above (ISTA 1H)

ISTA 1G Package Testing

ISTA 1G is a package test procedure applicable to individually packaged products weighing 150 pounds or less. Like ISTA 1A, it evaluates the strength and robustness of the product and package combination without simulating actual environmental conditions. The primary difference between ISTA 1A and ISTA 1G is the vibration testing, with ISTA 1A using fixed displacement vibration and ISTA 1G specifying random vibration.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Vibration | Random Vibration | Required |

| 3 | Shock (alternative methods allowed-select one test type) | Package Drop Test or Inclined Impact or Horizontal Impact | Required |

ISTA 1H Package Testing

ISTA 1H is a protocol for individually packaged products weighing more than 150 pounds. ISTA 1H is the same as ISTA 1B with the exception that ISTA 1H specifies random vibration. The test sequence is listed below.

| Sequence | Test Category | Test Type | For ISTA Certification |

| 1 | Atmospheric Preconditioning | Laboratory ambient temperature and humidity | Required |

| 2 | Vibration | Random Vibration | Required |

| 3 | Shock (alternative methods allowed-select one test type) | Package Drop Test (6 in) or Inclined Impact (69 in/sec) or Horizontal Impact (69 in/sec) | Required |

| 4 | Shock | Rotational Edge Drop (8 in) | Required when not testing face 1 |

ISTA 1 Series: Comprehensive Testing for Optimal Product Shipping and Delivery

ISTA package testing standards play a pivotal role in ensuring that products arrive in optimal condition at their destinations. These tests help manufacturers and distributors evaluate the durability and performance of their packaging and compare different packaging and product design alternatives. To ensure their products meet these standards, companies can rely on professional package testing services from accredited laboratories, delivering a safe and satisfying experience.

DES provides package testing services to the medical device, electronic, automotive, and aerospace industries within their environmentally controlled, accredited laboratory. Please contact an expert if you have any questions.