A vibration resonance occurs when equipment or a product is exposed to an external forced vibration occurring at one or more of its natural frequencies. The resulting product response vibration is amplified and can be huge! Vibration resonances can cause severe damage to products and significantly shorten their life. Examples of vibration resonances can be seen below and in our video page.

A natural frequency is the frequency at which a system will oscillate after an external force is applied and then removed. All objects have a natural frequency at which they vibrate. Most products have many natural frequencies.

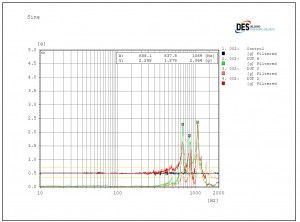

During vibration testing using vibration shakers, a sinusoidal vibration resonance scan or resonance search is used to study resonances in products. When performing a resonance scan, the vibration table exposes the product to controlled forced vibrations through a range of frequencies in an effort to study the product response vibrations. The forced vibration levels are low (typically ½ G) and are considered non-damaging. The product response accelerations are compared to the controlled table accelerations. Any amplification equal or greater than 2 to 1 is typically considered a resonance. The frequency at which this occurs is called a resonance frequency. DES has seen very severe resonance peaks greater than 20 to 1! A typical resonance scan plot is shown below. As an example, the product (DUT) response acceleration is 2.288 G’s at 688.1 Hz. The table accelerations (Control) are ½ G at 688.1 Hz. Thus, 688.1 Hz is considered a resonance frequency because the product to table acceleration ratio is 2.288G/0.5G = 4.576, which is greater than 2 to 1.

Some random vibration test specifications such as RTCA DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) require a sinusoidal vibration resonance scan before and after the test along each axis. Any significant change in the resonance scan results could be sign of damage or product failure.

The most famous failure due to resonance was the catastrophic Tacoma Narrows Bridge collapse as seen in our blog article Vibration Response of Products. When products are exposed to vibrations near their natural frequencies, fatigue failures from a vibration resonance can occur. Compressors and motors are examples of equipment that could generate significant vibrations. Products installed near such equipment should not have natural frequencies near their running speed.

In order to prevent early fatigue failures in your product, DES is capable of testing and analyzing the vibrational response of your product using their wealth of knowledge and vibration analysis software.

Nice article it’s very useful