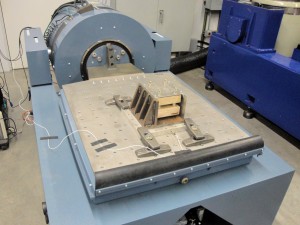

DES recently performed fastener vibration testing per MIL standard, MIL-F-25173A. MIL-F-25173A is a military specification aimed at determining qualification criteria for aircraft fasteners and equipment. In this case, DES focused on the vibration testing of a particular fastener to be used in aircraft applications. Tests were conducted on DES’s Unholtz-Dickie Electrodynamic Shaker. The MIL-F-25173A standard requires specimens to be subject to sinusoidal vibration testing, cycled between 10 and 55 Hz uniformly and with a constant 0.06 inDA displacement. Tests shall span the course of 90 minutes over three perpendicular axes.

DES recently performed fastener vibration testing per MIL standard, MIL-F-25173A. MIL-F-25173A is a military specification aimed at determining qualification criteria for aircraft fasteners and equipment. In this case, DES focused on the vibration testing of a particular fastener to be used in aircraft applications. Tests were conducted on DES’s Unholtz-Dickie Electrodynamic Shaker. The MIL-F-25173A standard requires specimens to be subject to sinusoidal vibration testing, cycled between 10 and 55 Hz uniformly and with a constant 0.06 inDA displacement. Tests shall span the course of 90 minutes over three perpendicular axes.

As you can imagine, the stresses of this test can be relatively severe and justifiably so due to the nature of aeronautical environments. However, vibration is not the only stress aircraft equipment is tested for. Environmental stresses such as altitude, temperature and shock are also typically seen by most aircraft equipment. All of these stresses play a role in reducing a product’s reliability. Therefore, it is important for aircraft equipment manufacturers to test to the proper specifications in order to ensure proper safety when flying. DES can help you decide what test specifications are best for your product based on their considerable experience and knowledge.