Shock Testing

Shock testing is performed to evaluate whether items can withstand high G force, short duration impulse loads. What sets DES apart from other labs is our in depth experience and technical capability to understand and reproduce the most complicated shock profiles. DES has tested to the most complex requirements on products that are used in outer space, rockets, missiles, military environments, etc.

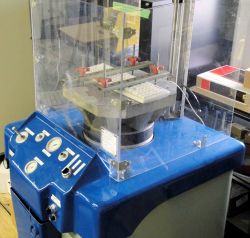

DES has numerous Shock Capabilities using Drop Tower and Pneumatic Shock Machines

Shock Test at DES

Shock Test Specifications:

Some common shock test standards are:

- EIA-364-27 Mechanical Shock (Specified Pulse) Test

- GMW 3172 General Motors Specification for Electrical/Electronic Components – Environmental/Durability

- IEC 60068-2-27 Shock

- IEC 60068-2-31 Rough handling shocks

- MIL-STD-202 Department of Defense Test Method Standard for Electronic and Electrical Component Parts

- MIL-STD-750 Test Methods for Semiconductor Devices

- MIL-STD-810 Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests

- MIL-STD-883 Department of Defense Test Method Standard for Microcircuits

- RTCA DO-160 Environmental Conditions and Test Procedures for Airborne Equipment

- SAE J1455 Recommended Environmental Practices for Electronic Equipment Design in Heavy-Duty Vehicle Applications

Shock Testing Capabilities:

- Up to 9,000 lbf shock loads using an ED Shaker

- Accelerations of 5,000 G and higher with shock amplifier

- Shock pulse duration range of 0.1 to 140 milliseconds

- Half-Sine, haversine, square or trapezoid, and saw-tooth shock waveforms

- Ability to apply many repetitive shock impulses

- Many high speed data acquisition channels

- Shock Response Spectrum (SRS) Analysis

Why Shock Testing is Important

- You need to know what your product’s fragility level is. DE Solutions uses shock testing to determine how well your product will hold up during handling and transportation.

- In the event of a crash, you’ll need to know if your product has any parts that break off and/or eject.

- Is your product destined for outer space or military environments? DE Solutions can perform shock testing to determine if your product is strong enough to withstand high G force and short duration impulse loads.

Related Blogs

If you would like to learn more about our shock testing services, please read these related articles from our blog:

- Long Duration Half Sine Shock

- Classical Shock Testing

- RTCA DO-160G Vibration and Shock Testing

- MIL-STD 810, Method 516, Shock Testing Overview

- MIL-STD 810, Method 516, Shock Testing Procedure I – Functional Shock

- MIL-STD 810, Method 516, Shock Testing Procedure II – Transportation Shock

- MIL-STD 810, Method 516, Shock Testing Procedure III – Fragility

- MIL-STD 810, Method 516, Shock Testing Procedure IV – Transit Drop

- MIL-STD 810, Method 516, Shock Testing Procedure V – Crash Hazard Shock